Rumored Buzz on Premier Aluminum Llc

Rumored Buzz on Premier Aluminum Llc

Blog Article

The Buzz on Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc - QuestionsThe Buzz on Premier Aluminum LlcThe Best Strategy To Use For Premier Aluminum LlcFacts About Premier Aluminum Llc Uncovered

(http://go.bubbl.us/e739a3/4118?/PastePremier-Aluminum-LLC)Making use of low cost and unqualified providers can cause high quality problems, and threw away time and money in the lengthy run. To help you with the process, right here are some things to take into consideration when picking the best metal casting supplier.

For instance, a business that only utilizes the financial investment spreading process will certainly try to sell you on why that procedure is best for your application. Yet suppose utilizing the sand spreading process is best for you and your needs? Rather, try to find a distributor that supplies a series of casting processes so the very best alternative for YOU is chosen

If collaborating with a solitary resource for all of your casting requires is essential to you, the supplier requires to be diverse in its abilities. When combined with various other integrated capabilities, this can assist simplify and compress the supply base. When choosing the ideal casting supplier, cautious consideration ought to be offered to high quality, solution, and price.

Everything about Premier Aluminum Llc

Customers increasingly select spreading providers that have machining abilities. This can stay clear of dispute if issues are discovered during machining. If a 3rd party is machining, it may result in "finger-pointing" regarding that is at mistake. Is it a spreading issue or a machining concern? If the casting supplier discovers a problem during machining, the trouble is solved much faster without any disagreement over whose mistake it is.

Trouble or no, integrated machining simplifies the supply chain and decreases dealing with time and delivery expense before the product makes it to the consumer. What do you require from your spreading provider? Are you seeking someone to simply deliver a metal element to your front door or do you require extra? For instance, if you do not have in-house metallurgy competence, verify that the supplier can supply advice in choosing the appropriate alloy based upon your details application - Aluminum Casting.

Some foundries are minimal or specialized. Make sure the distributor can meet all your material or alloy requirements to remove the need for several suppliers.

What Does Premier Aluminum Llc Do?

Research the vendor's internet site. navigate to this website Talk to a sales representative or company affiliate.

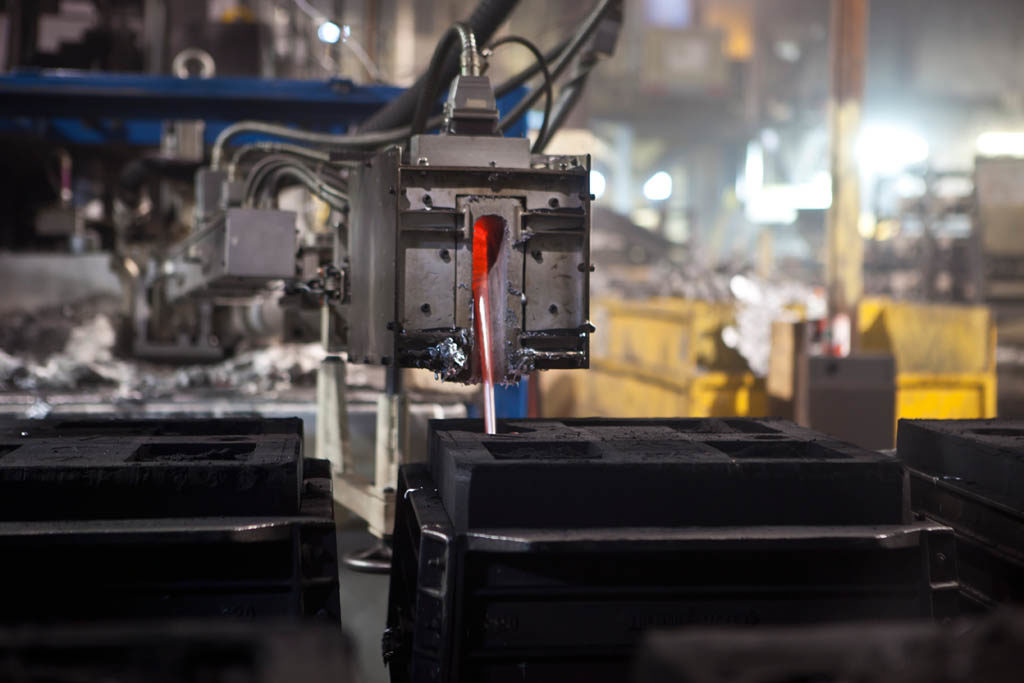

Aluminum is also lightweight and has good rust resistance, making it suitable for applications where weight and toughness are very important aspects. Additionally, light weight aluminum spreading is a cost-effective approach of manufacturing, as it needs less power and resources than various other techniques. Iron spreading, on the other hand, includes putting molten iron right into a mold to create a preferred shape.

The 9-Second Trick For Premier Aluminum Llc

Iron casting is also able to stand up to high temperature levels, making it appropriate for use in applications such as engine parts and industrial equipment. Nevertheless, iron casting can be more costly than light weight aluminum spreading due to the greater cost of basic materials and the energy called for to thaw the iron. When deciding in between light weight aluminum spreading and iron casting, it is very important to take into consideration the particular demands of the application.

In final thought, both aluminum spreading and iron spreading have their own special benefits and downsides. There are 3 sub-processes that drop under the group of die spreading: gravity pass away spreading (or irreversible mold spreading), low-pressure die spreading and high-pressure die spreading. To get to the ended up item, there are three main alloys used as die casting product to pick from: zinc, light weight aluminum and magnesium. Report this page